3D Printing on the Mid North Coast

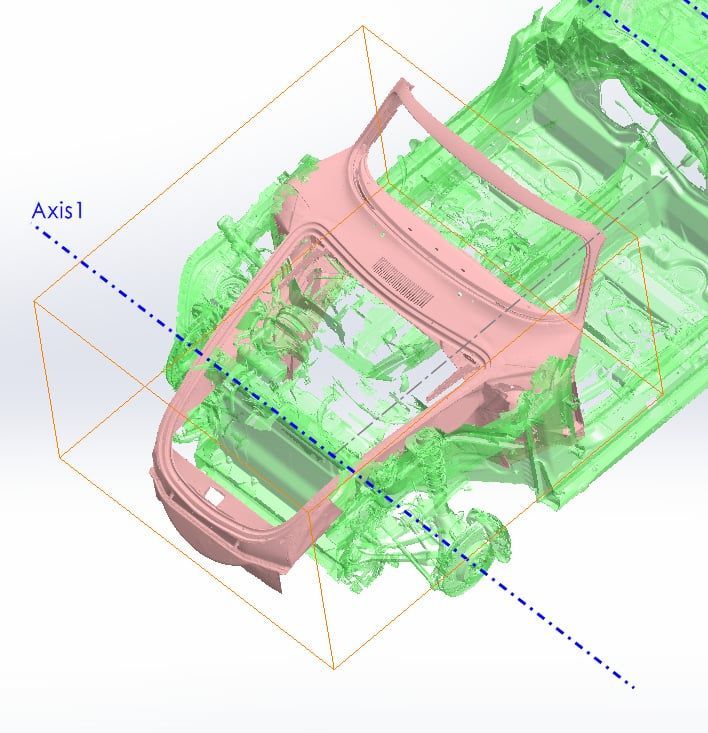

Micron-accurate 3D scanning

3D printing & prototyping for custom parts

Fast turnaround, low volume

Local area's only SLS, SLA & DLP specialists

Request a Call Back

Thank you for contacting 3D Tech.

We will get back to you as soon as possible.

Please try again later.

Mid North Coast 3D Printing

24/7

Open by Appointment.

Not every part can be mass-produced, and that’s where 3D printing shines. At 3D Tech, based on the Mid North Coast, we use computer-aided design (CAD) and reverse engineering to bring highly complex shapes to life. This is perfect for designs that can’t be produced through injection moulding or traditional techniques.

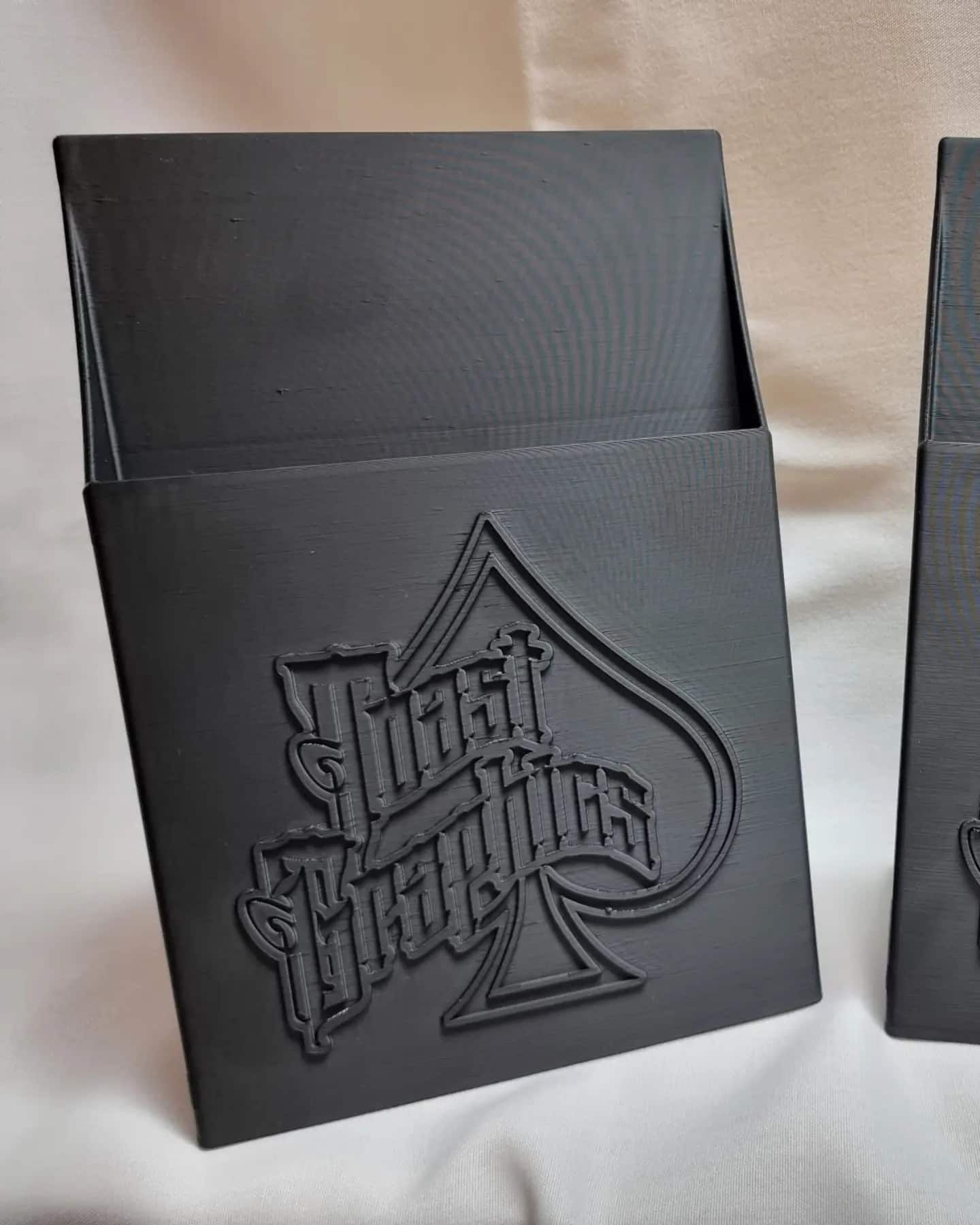

From functional prototypes to one-off components, we print in high-performance materials like carbon fibre nylon, ABS, PLA and rubber, giving you tough, flexible, and detailed results. Whether you’re developing a new product or replacing a unique part, or even creating 3D printed toys, our service is fast, reliable and cost-effective for low-volume runs. We also work with clients to improve and evolve their designs during prototyping, offering insight from real-world engineering experience.

We offer services in:

- Fused Deposition Modelling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Digital Light Processing (DLP)

Ready to print your next project? Contact us today for advice and quotes.

Flexibility to choose the right process for your part or project.

High-Performance Materials

Engineering-Led Expertise

Servicing Australia-Wide

Smart Design Solutions

Our 3D printing service goes beyond pushing "print" on a machine. We help refine your ideas, prototype them effectively, and, if needed, connect you with larger-scale production partners through our trusted industry contacts. This flexibility makes us ideal for creators, manufacturers, and businesses that need something custom but don’t want the cost or delay of traditional production methods.

Not only do we offer printing options across Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), Stereolithography (SLA) and Digital Light Processing (DLP), but we are the only specialists with the equipment necessary to provide SLS, SLA and DLP services across the entire Mid North Coast.

Whether you’re tackling a brand-new concept or looking to replicate something that’s no longer available, our combination of design, material versatility and manufacturing know-how gives you a competitive edge.

Additive Manufacturing 3D Printing

Additive manufacturing is the process of creating objects by adding material layer by layer. It’s perfect for producing detailed, custom parts without the need for expensive moulds or tooling. We use computer-aided design (CAD), expert engineering drafting and 3D scanners to create suitable custom designs that are ready for printing.

Using materials like carbon fibre nylon, PLA, ABS and rubber, additive manufacturing makes it easier to design, test, and manufacture complex components on demand. This method is ideal for low-volume production, rapid prototyping, and parts with intricate geometries.

Subtractive Manufacturing Production

While 3D printing builds parts up, subtractive manufacturing uses reverse engineering techniques to cut, drill or mill material away from a solid block to create a final shape. It’s often used when parts need to be made from tough materials like metal or when the finish or tolerances need to be especially precise. Subtractive techniques are a great solution for jobs where additive methods aren’t suitable, and they’re often used alongside 3D printing for hybrid projects.

3D Prototyping Services

Prototyping is where great ideas take shape—literally. With 3D printing, you can test and refine designs quickly without committing to large production costs. Whether you're adjusting dimensions, testing fit and function, or exploring a new concept, prototyping lets you move from idea to physical model in a matter of days. We’ll work with you to improve the design and even assist with scaling if you decide to go into production.

Wondering what we can do for your business?

What can be made with 3D printing?

3D printing can be used to create a wide variety of objects—from simple brackets and enclosures to intricate, custom-fit mechanical parts. We can even manufacture toys!

It’s ideal for prototyping, functional testing, and producing components that are difficult or expensive to manufacture using traditional methods. In many cases, 3D printing enables complex geometries that can’t be made through injection moulding or machining, including internal channels, organic shapes, and interlocking parts.

What materials are used in 3D printing?

Modern 3D printing uses a range of materials depending on the required strength, flexibility and finish. Common options include PLA (a general-purpose plastic), ABS (strong and impact-resistant), carbon fiber nylon (lightweight and high-strength), flexible rubber-like filaments, a range of resin materials as well as various metals. The choice of material affects how the part performs in real-world applications, making it important to select the right one for your needs.