CAD Design on the Mid North Coast

Micron-accurate 3D scanning

3D printing & prototyping for custom parts

Fast turnaround, low volume

Local area's only SLS, SLA & DLP specialists

Request a Call Back

Thank you for contacting 3D Tech.

We will get back to you as soon as possible.

Please try again later.

Mid North Coast CAD Design

24/7

Open by Appointment.

Innovation can start with something as simple as a sketch on paper, but trying to get the dimensions just right can stall everything and totally stop your project's momentum. 3D Tech on the Mid North Coast removes that roadblock by turning rough concepts—or worn-out components—into accurate, editable CAD models. Using metrology-grade scanners and professional design software, we capture every contour, recreate missing geometry and build a digital foundation ready for machining, printing or analysis.

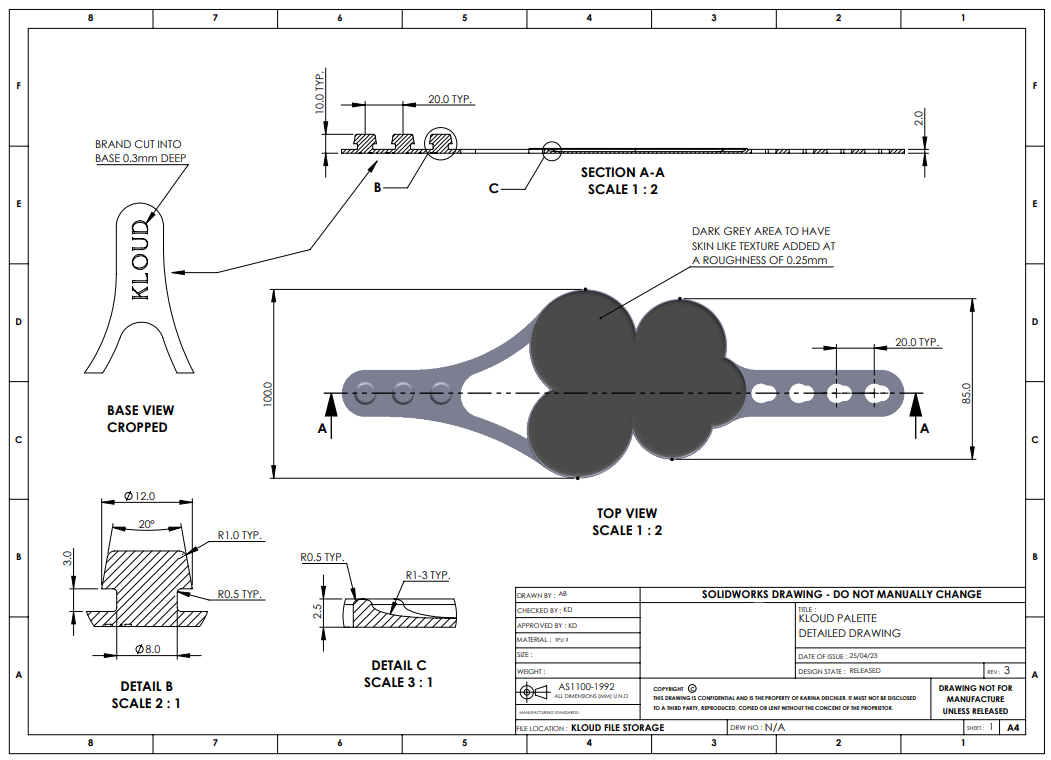

Modern CAD design streamlines project timelines, cuts material waste and lets you visualise changes before a single tool touches metal. Our designers specialise in reverse-engineering legacy, out-of-production or custom components, translating real-world ideas into data that speaks the language of engineers.

Ready to move from guesswork to guaranteed fit? Contact us today and put precision on your side.

Our scan data can be directly overlayed on your CAD data to show even the most intricate of deficiencies and tolerance points

Precision CAD Modelling

Reverse Engineering Experts

Scan-to-Design Workflow

Inspection & Quality Control

Accurate inspection starts with reliable data. We use high-resolution 3D scanning to measure parts against their original CAD models, highlighting deviations in shape, wear or manufacturing accuracy. This non-contact process is ideal for quality control, especially in industries where precision is critical. Whether you're verifying production consistency or checking tolerances on a legacy part, we deliver clear, traceable results that help prevent errors and reduce downtime.

Reverse Engineering to Ready-to-Build Plans

Old drawings fade, suppliers discontinue parts and custom modifications rarely come with documentation. Reverse engineering bridges those gaps. Our process begins with a high-resolution scan that records millions of points on the part’s surface. We then use specialist software that converts that point cloud into a clean, parametric CAD model, preserving critical tolerances while allowing updates or improvements.

Our accurate digital replicas unlock a host of possibilities. Manufacturers can reproduce obsolete components in small batches without costly re-tooling. Designers can analyse stress points, simulate loads and refine shapes for better performance. Maintenance teams gain reliable reference files for future repairs, and innovators can blend legacy geometry with new features to create hybrid solutions. In short, reverse engineering extends the life of valuable assets and speeds the journey from concept to production-ready drawing.

Engineering Drafting

Clear drawings turn brilliant models into buildable parts. Our professional engineering drafting translates complex 3D geometry into concise 2D views with dimensions, tolerances and material notes arranged to international standards. We make sure manufacturers get unambiguous instructions, inspectors gain exact reference points and project managers avoid costly rework. Whether you need fabrication sheets, assembly layouts or compliance documentation, our accurate drafting keeps every stakeholder on the same page from workshop to final installation.

Wondering what we can do for your business?

What is CAD design and why is it important in engineering?

Computer-aided design (CAD) is the practice of creating detailed digital models that define a part’s geometry, dimensions and material properties. Engineers rely on CAD files to run simulations, generate manufacturing instructions and ensure consistent quality across production runs. Precise CAD data minimises errors, reduces prototyping cycles and enables swift revisions when requirements change.

How does reverse engineering work when original drawings are lost?

Technicians first perform a non-contact 3D scan of the physical part, capturing its exact shape and size. Software stitches the raw point cloud into a watertight mesh, which is then converted into a solid or surface model. Designers add parametric constraints so features can be edited just like a native CAD file. The result is a fully functional drawing set that can be machined, printed or analysed even though no original documents existed.

Are reverse-engineered designs legal to use for manufacturing?

Legality depends on patents, trademarks and contractual obligations. In general, reproducing a part for maintenance, repair or operational continuity is permissible when intellectual-property rights have expired or do not apply. However, mass-producing patented items for commercial sale without permission can infringe on protected designs. Always verify ownership status and seek legal advice if the part is still under active patent or exclusive licence.